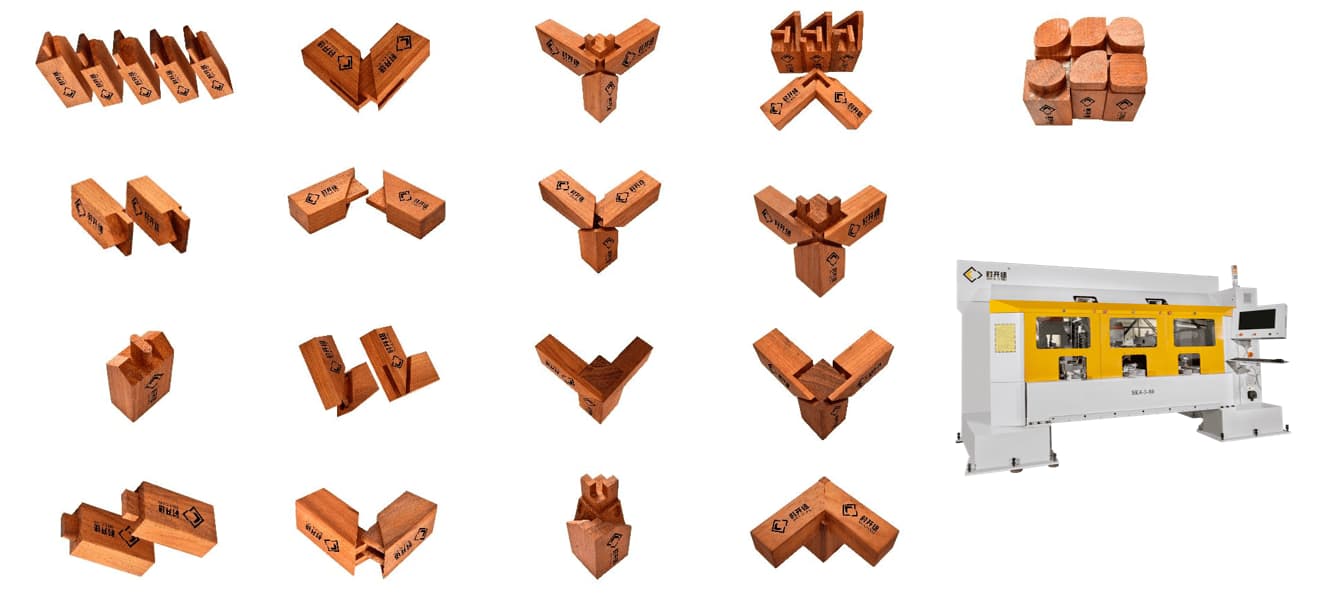

SK4-3-80 is a high-speed mortise and tenon machining center with directional research and development. It is more convenient and humanized to operate. It can produce various forms of mortise and tenon, covering 95% of the conventional mortise and tenon structures on the market.

The production and processing are all modularized, no need to calculate the processing data, only need to input the material specifications and other data.

Dozens of mortise and tenon processing are merged into one equipment (continuous upgrading), which is widely used in the production and processing of furniture mortise and tenon.

| Size: | 3900(L)*2763(W)*2476(H) |

| Material size: | 80(W)*80(H) |

| Control system: | Independently develop control system (without third-party service), support customization and free function upgrading. |

| Computer configuration: | Windows control interaction system. |

| Servo parameters: | Delta servo,Moving speed:30000mm/min |

| Spindle parameters: | 1pcs (Milling cutter spindle) :12000rpm,5.5Kw 1pcs (Milling hole spindle) :18000rpm,3.5Kw 1pcs (Milling hole spindle) :18000rpm,1.5Kw |

| Processing system: | System automatic control: milling cutter and milling hole processing. |

| Tool specification: | Bore diameter:φ30,Milling hole spindle:ER25 |

| Material and weight: | Dragon Gate+ Sheet metal,4000Kg |

| Voltage/Frequency/Power | 3P 380V/50Hz +E 16.5Kw(MAX) |

| Suction port: | Φ140*2 |

| Air pressure: | 0.5~0.8Mpa,φ10 |

| lubricating oil: | Hv32 |

Advantage

Advantage

Drive the innovation of smart tenon joints and build a model of the smart industry together.

Suzhou shikainiu CNC Equipment Co., Ltd. is a high-tech enterprise in Jiangsu Province. The company inherits the traditional Chinese furniture manufacturing technology and reproduces various tenon and mortise processes through modern equipment. The main products are optimizing sawing, tenon and mortise production, door and window production.

Add:18-2 Tiandoli Road, Yangcheng Lake Town, Xiangcheng District, Suzhou, Jiangsu

request a quote