Suzhou shikainiu CNC Equipment Co., Ltd. inherits the traditional Chinese furniture manufacturing technology and reproduces various tenon and mortise processes through modern equipment.

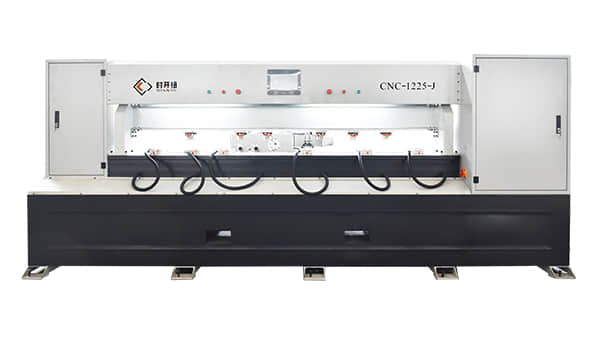

Wood drilling machine

Wood drilling machine CNC-1225-J has the first in the woodworking industry: CNC + module dual system, can be connected to TopSolid and other design software and MES system, can use UG programming modeling operation, can use the built-in module that has been established for operation.

ShikaiNiu Wood drilling machine CNC-1225-J has the functions of processing square holes, round holes, mortise and tenon, milling, tenon, and groove, etc., and can be programmed according to the actual customer’s process requirements, simple size input can complete complex Processing requirements and the function of automatic program reversal during multi-sided processing.

Wood drilling machine has dozens of tenon and groove processing techniques, which can effectively replace traditional inefficient equipment such as hanging gongs, floor gongs, vertical milling, rocking drills, dovetail tenons, square hole drills, etc. Special features such as suspension.

Miter door machine

Highly intelligent mortise and tenon-3station, only need the width and thickness of three materials (five data), automatically calculate the angle without manual intervention, saving time and effort.

Highly intelligent mortise and tenon-3station can continuously process inclined tenon structure, which is accurate and efficient, easy to operate, and saves manpower and material resources for the furniture industry. It is a real low cost mortise and tenon-3station.

Shikai Niu’s Highly intelligent mortise and tenon-3station R&D team, dedicated and talented, has been keeping up with the forefront of technology and is committed to developing the latest design mortise and tenon-3station. Our Highly intelligent mortise and tenon-3station R&D team Always stand in the customer’s position, constantly upgrade technology, with the purpose of developing low cost Wood processing center, to help each of our customers reduce the input cost, and can also be customized according to customer’s process requirements. Provide customers with mortise and tenon-3station customized solution.

Door and window

Door and window NC-31 is specially designed for processing cabinets, doors and windows, floors, siding, etc. Whether it is whole house customization, door and window enterprises, or antique processing, Door and window can solve your problem of fast shipping. Core board, line milling, wall panel processing, etc., one-time molding; 45°, 90°, 135° framed doors and windows mortise-and-mortise structure processing, one-time molding, Door and window can also realize special process processing such as process lines.

Door and window can help you increase productivity, improve efficiency, increase yield, improve quality, save costs, and automate production.

ShikaiNiu Door and window can be customized according to the customer’s own needs to achieve intelligent manufacturing of high-quality solid wood furniture.

Mortise and tenon-3Station

Mortise and tenon-3Station SK4-3-80 is a high-speed mortise and tenon machining center with directional research and development. It is more convenient and user-friendly to operate. It can produce various forms of mortise and tenon, covering 95% of the conventional mortise and tenon structures on the market.

ShikaiNiu Mortise and tenon-3Station can keep the material unchanged and the machine head moving, which can improve the production efficiency by 40%, the production speed is fast, and the labor is effectively released.

Mortise and tenon-3Station, which is automated, numerically controlled, and informatized, solves the complex, precise, multi-variety, and small-batch production problems in solid wood processing.

Crosscut saw CNC

Crosscut saw CNC SJ-260R, is the optimal cutting saw for variable cutting speed and stroke, precise length setting. The functions of optimization, cut-to-length, material calculation and other functions are merged into one device, which can be applied to the production and processing of various linear wood and furniture.

The production capacity of Crosscut saw CNC can reach 3-6 times that of manual cutting saws. The scraps after cutting are automatically discarded. The optimized function achieves the highest yield and greatly improves production efficiency.

The difference between ShikaiNiu Crosscut saw CNC and cross-cut circular saw is that it obtains the best optimized solution through comparison, and the sawing accuracy, processing quality and processing speed are superior to the cross-cut circular saw.

It can be applied to the production and processing of all kinds of linear wood and furniture.

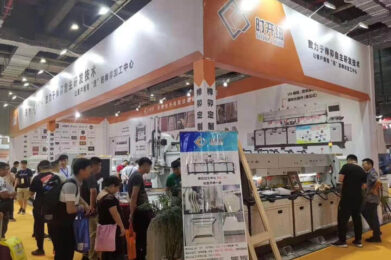

Drive the innovation of smart tenon joints and build a model of smart industry together

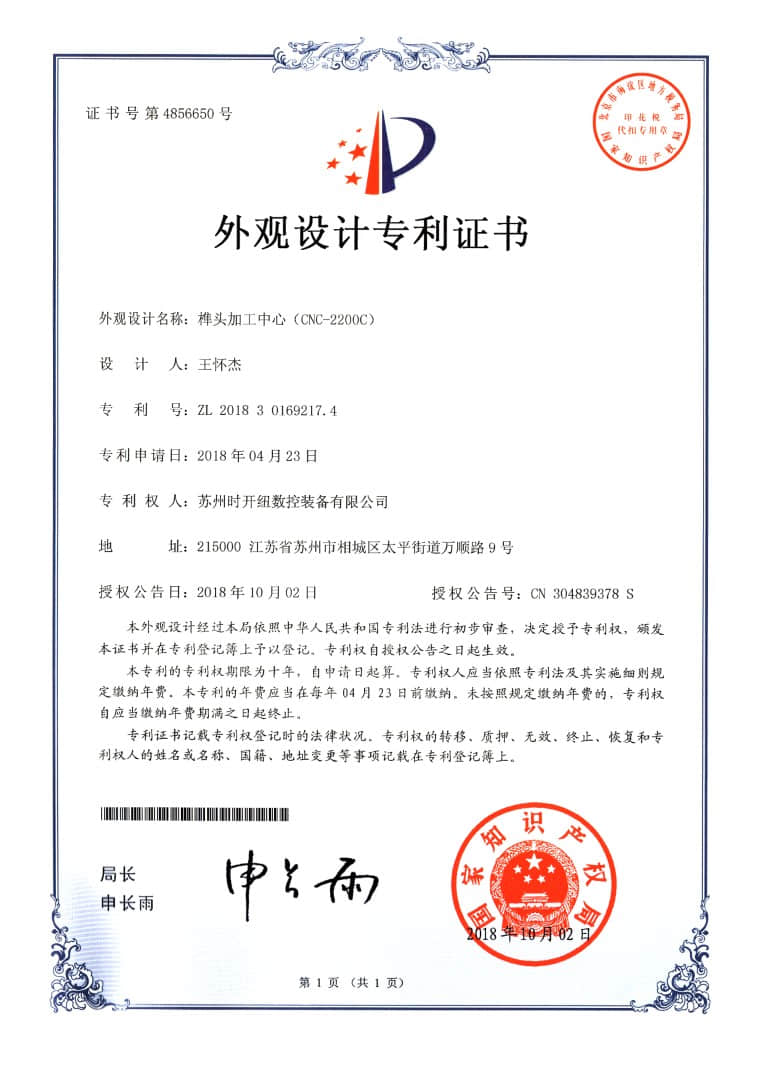

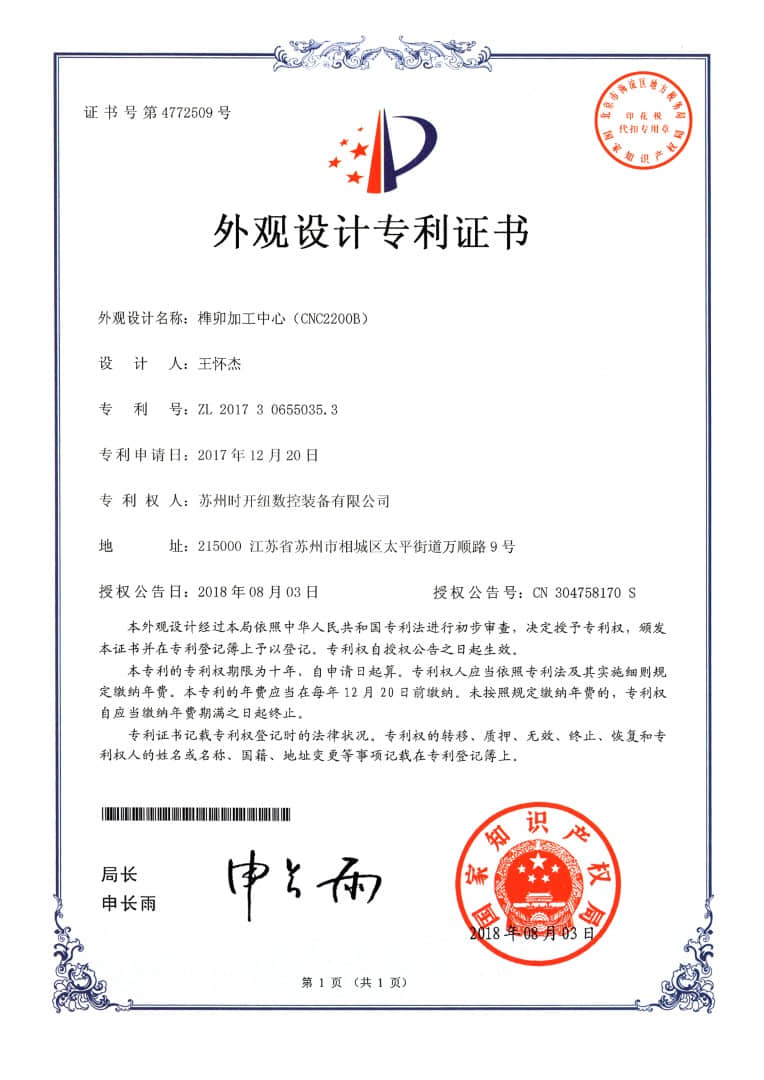

Suzhou ShikaiNiu is a high-tech enterprise focusing on the manufacturing of intelligent tenon and tenon joints processing equipment. Mainly engaged in the development and manufacture of various types of furniture, mortise and tenon, modeling processing and other full series of high-end automatic tenon and tenon processing equipment, and design a series of optimized solutions for customers in the production and processing process. With many years of experience in equipment production, the products run through the furniture industry, covering every furniture production city in China, and going to the world, winning the praise and recognition of our customers.

ShikaiNiu CNC is a leading manufacturer of furniture mortise and tenon structure processing equipment, providing customers with a full range of software and hardware, system integration solutions, and professional tenon and mortise customization services, and guarantees the efficient operation of equipment with advanced technology.

ShikaiNiu has formed a strong technical service and marketing network with many partners and branch teams to provide customers with convenient services with a truly national layout and localized response.

ShikaiNiu takes the push of smart furniture production lines and smart tenon and tenon processing equipment as its corporate mission and aims to “drive smart tenon and tenon innovation and build a model of the smart industry together” to assist various industries in accelerating the establishment of their smart production lines and strive to become smart The most influential enterprise in the field of tenon and tenon processing equipment.

Focus on your core technology

Modular programming has a wealth of specifications and standards, providing a variety of rapid product solutions for furniture manufacturers.

The CNC numerical control system has a powerful independent programming operation function. It generates codes through UG, TOPSOLID, and other upper computer software, and imports the system to select the corresponding code for processing. Each type of equipment standard follows the requirements of its interface and organization, which also makes product upgrades and replacements very convenient, which makes dual-system solutions the first choice of more and more customers.

80% of tenon and tenon machines are more convenient, smarter and faster for you

Learn about us through FAQ

What is dual system?

The dual system is a high-end control system that integrates modular motion control and CNC numerical control system. It can truly realize the connection between the equipment processing system and the design and typesetting system.

What is the after-sales service form of Shikai Niu?

phone service

Shikai New York provides 7*12 hours hotline service for all products

Teaching Service: 0512-68411968

Sales service: 0512-68411918

online service

TimeKai New Technology website provides drivers, common problems and video tutorial downloads

Customers can log in to the official website http://www.shikainiu.com

Public number: Shikai Niu CNC

Query or download.

warranty service

Shikai Niu provides all standard products and purchased products during the warranty period

Repair or replacement service.

After-sales service

Professional after-sales team solves after-sales problems perfectly in time for customers

And visit customers regularly

System upgrade, second teaching

How can i return a product?

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged. It was popularised in the 1960s with the release of Letraset sheets containing Lorem Ipsum passages, and more recently with desktop publishing software like Aldus PageMaker including versions of Lorem Ipsum.

How long will it take to get my package?

It is a long established fact that a reader will be distracted by the readable content of a page when looking at its layout. The point of using Lorem Ipsum is that it has a more-or-less normal distribution of letters, as opposed to using ‘Content here, content here’, making it look like readable English. Many desktop publishing packages and web page editors now use Lorem Ipsum as their default model text, and a search for ‘lorem ipsum’ will uncover many web sites still in their infancy. Various versions have evolved over the years, sometimes by accident, sometimes on purpose (injected humour and the like).

What shipping methods are available?

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged. It was popularised in the 1960s with the release of Letraset sheets containing Lorem Ipsum passages, and more recently with desktop publishing software like Aldus PageMaker including versions of Lorem Ipsum.

Do you provide any warranty?

It is a long established fact that a reader will be distracted by the readable content of a page when looking at its layout. The point of using Lorem Ipsum is that it has a more-or-less normal distribution of letters, as opposed to using ‘Content here, content here’, making it look like readable English. Many desktop publishing packages and web page editors now use Lorem Ipsum as their default model text, and a search for ‘lorem ipsum’ will uncover many web sites still in their infancy. Various versions have evolved over the years, sometimes by accident, sometimes on purpose (injected humour and the like).

How can i cancel or change my order?

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged. It was popularised in the 1960s with the release of Letraset sheets containing Lorem Ipsum passages, and more recently with desktop publishing software like Aldus PageMaker including versions of Lorem Ipsum.

What You Need To Know About Wood Cutting

one. introduction Wood is a magical thing. After the wood is cut, it will change and shrink/expand/twist. Imagine if your desktop is 1 meter wide, under the influence of expansion (spring/summer) and contraction (autumn/winter), a 2% change equals 2cm. In …

-

Add:

18-2 Tiandoli Road, Yangcheng Lake Town, Xiangcheng District, Suzhou, Jiangsu -

Tel:

+86 0512 68411918 -

E-mail:

huaijie-wang@shikainiu.com - Telegram