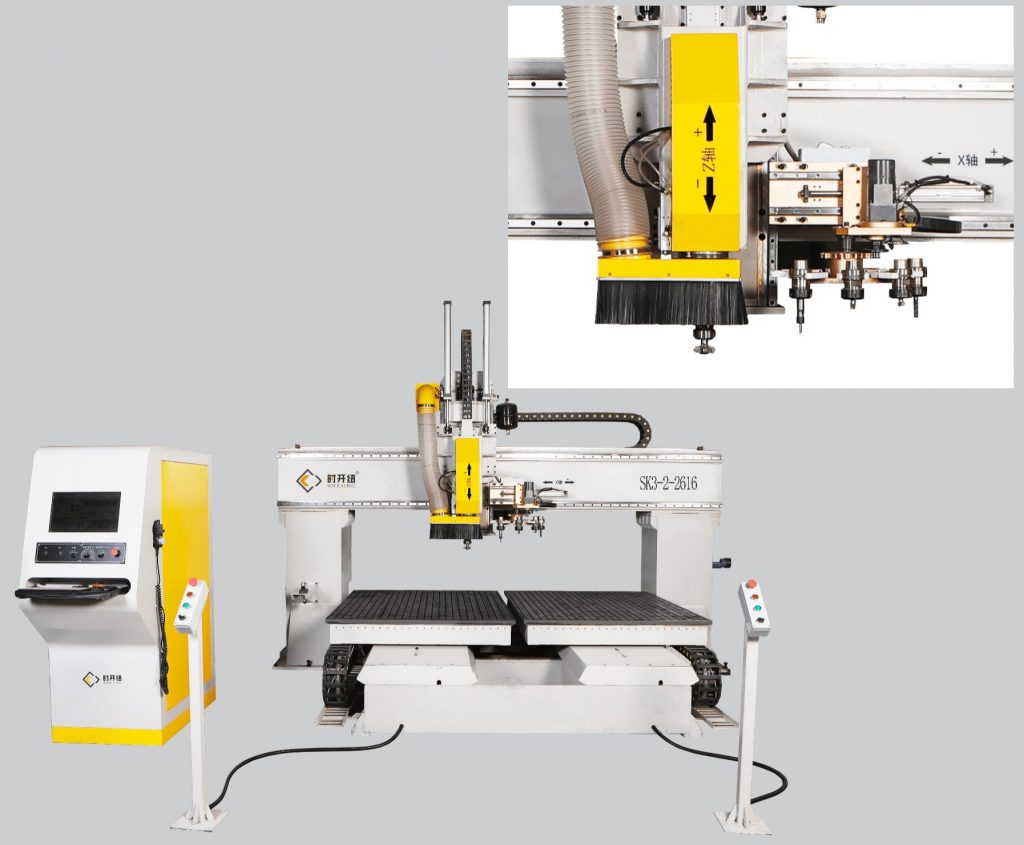

The 3-axis machining center SK3-2-2616 (-C, -D) is a CNC machining center developed for positioning heavy-duty milling.

The 3-axis machining center SK3-2-2616 (-C, -D) adopts the OSAI controller imported from Italy, the automatic tool-changing spindle imported from Italy, the high-end absolute value servo from Yaskawa from Japan, and the high-end configuration of Taiwan transmission system and electrical components imported from Japan.

Turning and milling machine is suitable for the production and processing of various molds, plates, and furniture.

High-standard accessories enable the workpiece to be machined on the shape accuracy, position accuracy, and workpiece surface side, and the 3-axis machining center SK3-2-2616 (-C, -D) meets various processing requirements.

| Size: | 4500(L)*3000(W)*3085(H) |

| Working bench size: | 1300*2(L)*1600(W),Two workbenches |

| Control system: | Italy OSAI controller |

| Computer configuration: | 3.3Ghz + 4G + 128G ssd + WiFi + LED(Display) |

| Servo system: | Yaskawa absolute value servo,6000mm/min |

| Spindle parameters: | Configuration1:

Hiteco 12000rpm,9.5Kw, Automatic tool change, HSK 63F ER40 Configuration2: Hiteco 12000rpm,12Kw, Automatic tool change, HSK 63F ER40 Configuration3: Composite spindle+Hiteco(9.5Kw or 12Kw), HSK 63F ER40 |

| Drive system | Imported screw rod, guide rail, and reducer. |

| Frequency converter: | Bosch Rexroth, heavy-duty |

| Tool magazine: | It is equipped with 8 position tool magazine,

including a tool measuring system: automatic detection and compensation of tool length. |

| Weight: | 5500Kg/6500Kg |

| Voltage/Frequency/Power | 380V/50Hz 3P+E,12.5Kw/18Kw |

| Suction port: | Φ100*1 |

| Air pressure: | 0.5~0.8Mpa,φ10 |

| lubricating oil: | Hv32 |

Precautions for the use of equipment

1. The operator must be familiar with the performance, operation and maintenance methods of the equipment. Strictly abide by the safe operation regulations of CNC equipment. Do not operate the machine without professional training.

2. The operator of the machine must wear protective equipment before using the machine to ensure safety. No gloves, scarves, etc. are allowed to operate.

3. The machine is not allowed to maintain, refuel, clean and adjust during operation.

4. Before working every day, check whether the lubrication system of the machine is in good condition. Do lubrication and maintenance work for the machine on time, usually once every two days.

5. Keep the environment around the equipment tidy and clean the machine frequently.

6. Operate strictly in accordance with the boot sequence in the machine manual.

7. Before the machine starts to work, it should be warmed up, and carefully check whether the lubrication system is working properly. If it has not been started for a long time, you can use manual lubrication to provide lubrication to each part; check whether the voltage, air pressure, and oil pressure meet the working requirements.

8. It is forbidden to lift the rotating spindle, workpiece or other moving parts by hand or by any other means.

9. During the operation of the equipment, the operator shall not leave the post, and the machine tool shall immediately stop working if an abnormality is found, and shall be inspected and repaired.

10. When the machine is working, non-operators should not stand on both sides to watch, so as to avoid accidents.

11. During the operation of the machine tool, do not remove chips, and avoid touching the moving parts of the machine with your hands; when removing chips, you must use certain tools to avoid being scratched by the chips;

12. Generally, two persons are not allowed to operate the machine at the same time. But when a certain task requires two or more people to complete it together, they should pay attention to coordinate their actions with each other.

13. The operator must stop the machine when changing tools, workpieces, adjusting workpieces or leaving the machine tool while working.

14. If you find that the lathe is running abnormally or malfunctions during processing, you must stop it for inspection immediately to avoid danger.

Drive the innovation of smart tenon joints and build a model of the smart industry together.

Suzhou shikainiu CNC Equipment Co., Ltd. is a high-tech enterprise in Jiangsu Province. The company inherits the traditional Chinese furniture manufacturing technology and reproduces various tenon and mortise processes through modern equipment. The main products are optimizing sawing, tenon and mortise production, door and window production.

Add:18-2 Tiandoli Road, Yangcheng Lake Town, Xiangcheng District, Suzhou, Jiangsu

request a quote