Woodworking machinery automation technology

Using new technology to improve the degree of automation and production efficiency of woodworking machinery is also an important measure to achieve good energy saving and environmental protection.

(1) Woodworking machinery gradually from the previous mechanical way into the use of mechatronics technology. For example, some important equipment such as woodworking machinery tools and workpieces are monitored by installing sensors in the process of operation, which helps to ensure that they work normally and can ensure the quality of furniture manufacturing and processing. For example, in the scanning, identification, and tracking of workpieces, we can use high-resolution image processing technology to complete, thus helping to improve the quality of furniture and wood processing.

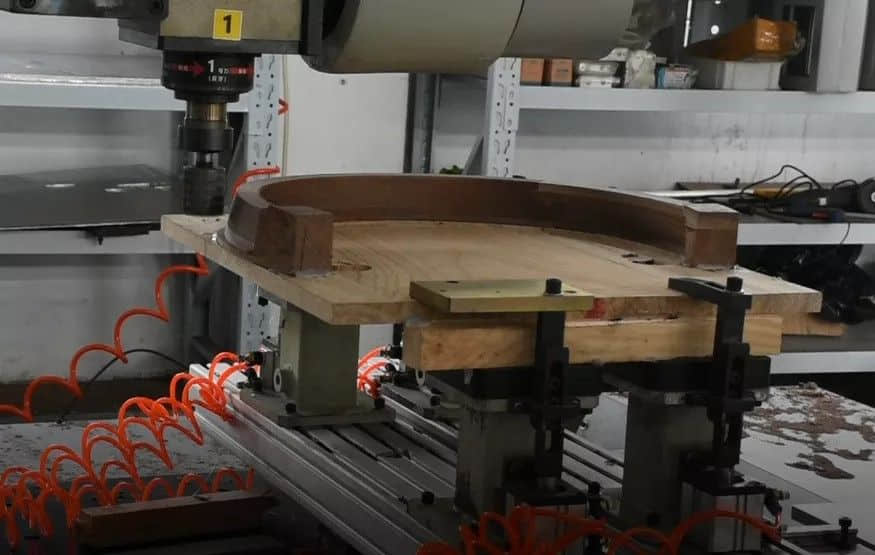

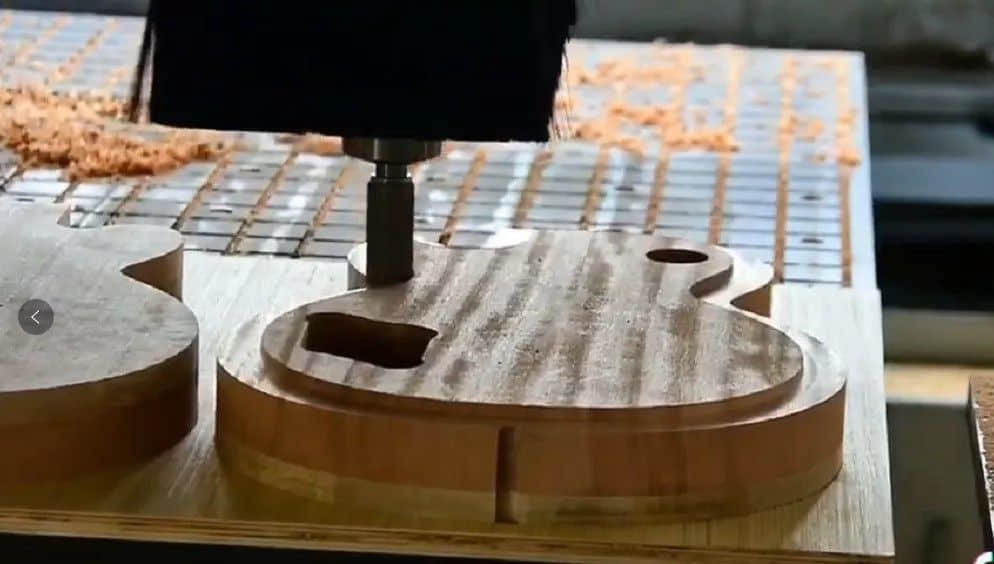

(2) At present in the flexible machining system, CNC processing, and automatic production lines, including numerical control and information technology, some advanced technology has also been applied to them. At present, China’s woodworking machinery is also in this situation computer digital control technology has been widely used, such as the more common tenon machine, doors and Windows processing center, fine cutting optimization saw, three-axis, and five-axis processing center.

In addition, flexible machining and manufacturing systems and intelligent integrated machining systems are becoming increasingly mature. For example, the use of small-diameter wood in the production of aggregate wood can better reduce the waste of wood resources. The core of this production lies in the use of computer integrated manufacturing, in simple terms, is in the wood quality identification, strength classification, tool selection, automatic production line, plate composite press and finished product output and many other aspects are automated control by the computer.

(3) Woodworking machinery in the use of a variety of advanced control technology with adaptive and intelligent control function, so not only conducive to improving wood processing accuracy, utilization rate, and manufacturing efficiency, but also can effectively reduce the use of woodworking machinery energy consumption and reduce pollution.

(3) Woodworking machinery in the use of a variety of advanced control technology with adaptive and intelligent control function, so not only conducive to improve wood processing accuracy, utilization rate and manufacturing efficiency, but also can effectively reduce the use of woodworking machinery energy consumption and reduce pollution.

(1) Adaptive control of woodworking machinery, its work according to the pre-set evaluation indicators of wood processing, such as tool wear, material hardness and other situations and automatically change the processing parameters, so as to ensure that wood processing can meet the requirements of evaluation indicators.

② Woodworking machinery intelligent control, is mainly the use of intelligent machines with independent drive, and according to the corresponding target to control the wood processing process.