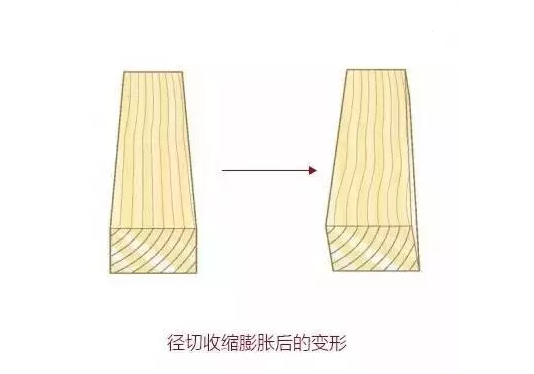

China upcut saws manufacturer has always believed that wood is a magical thing. After shearing, it keeps changing, shrinking/expanding/twisting. Imagine if your desktop is 1 meter wide, under the influence of expansion or contraction, a 2% change equals 2 cm. In addition to the impact on the appearance, its changes can also destroy the structure of the table, causing the entire table to fall apart.

For the same wood, the internal structure and texture arrangement are fixed, but different cutting methods will allow us to see different wood grains and get different physical properties, and the wood will have great changes in the future. According to the degree of influence, China upcut saws manufacturer divides the cutting methods of wood into three groups, namely string cutting, engraving cutting and radial cutting.

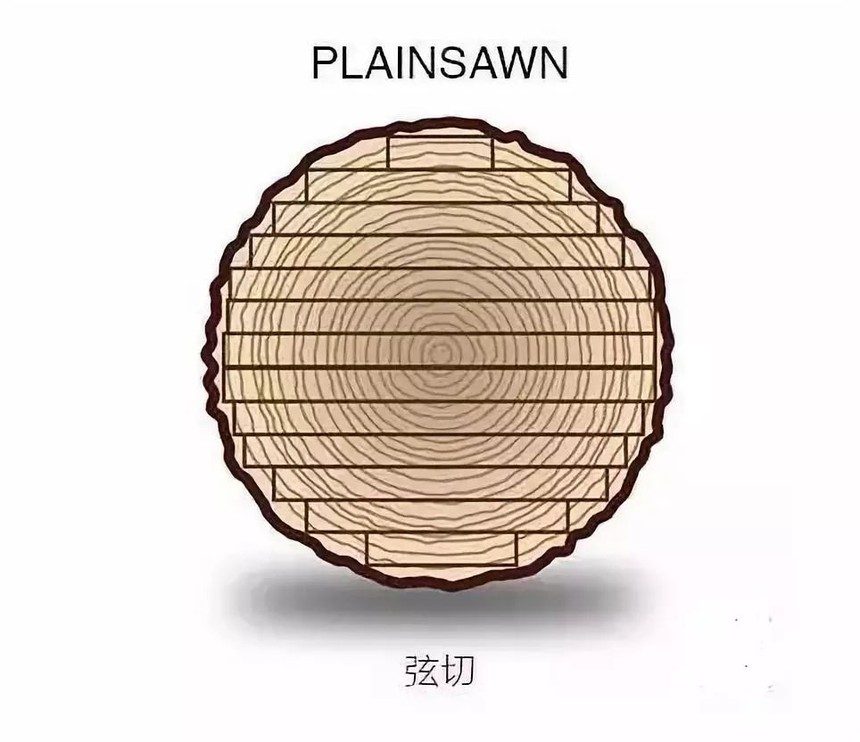

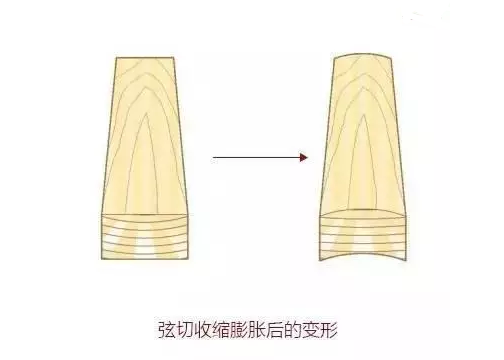

【String cut】

That is, it is sawed along the main axis of the trunk, or the direction of the wood grain, perpendicular to the radius of the trunk section.

advantages of chord cutting are the easiest to operate, the least wasteful, and the most cost-effective. The sawn boards are wide, and there will be “big patterns” and “landscape textures”. These beautiful wood grains, so there are many solid wood chord cutting boards on the market.

The disadvantage is that it is easy to deform, and the shrinkage and expansion are relatively large, which is 1.5 to 2 times that of engraving or radial cutting.

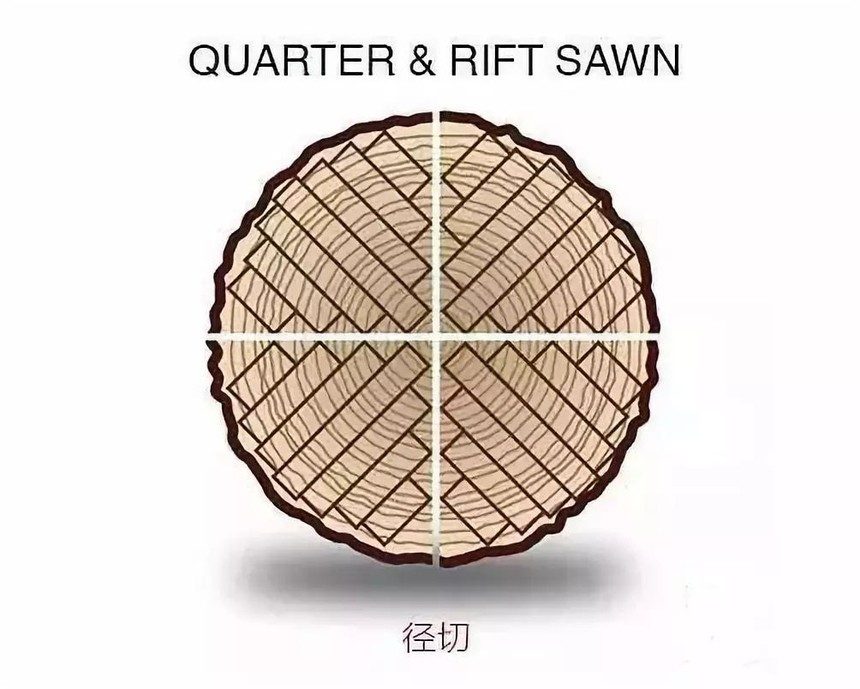

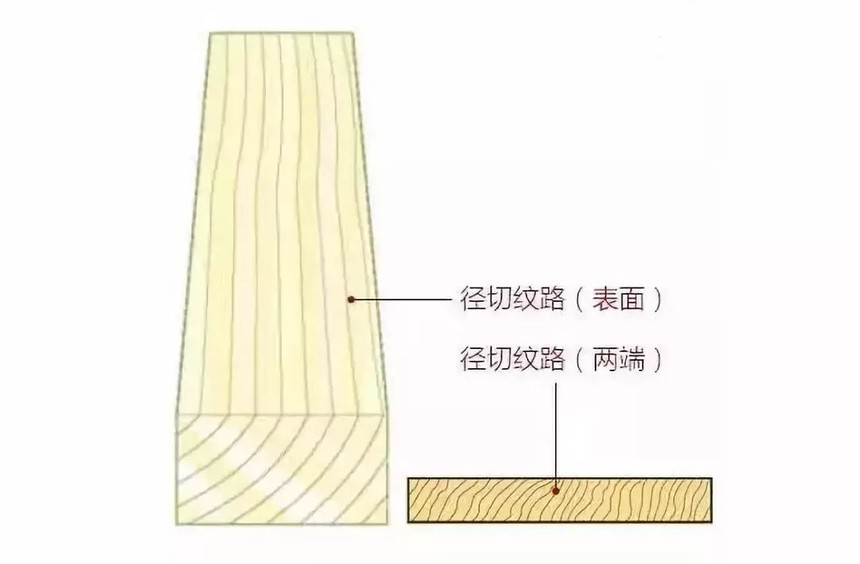

【Diameter cut】

That is, after cutting the stake into four parts, then cutting and sewing, the part far from the heartwood is called the diameter-cut plank. The diameter-cut plank is mostly straight-grained and stable in nature. The angle between the cross-section and the annual ring is 30-60 degrees.

The advantages of diameter cutting are high stability, mainly straight grain, moderate price, but the disadvantage is that it takes a long time and consumes a lot of materials.

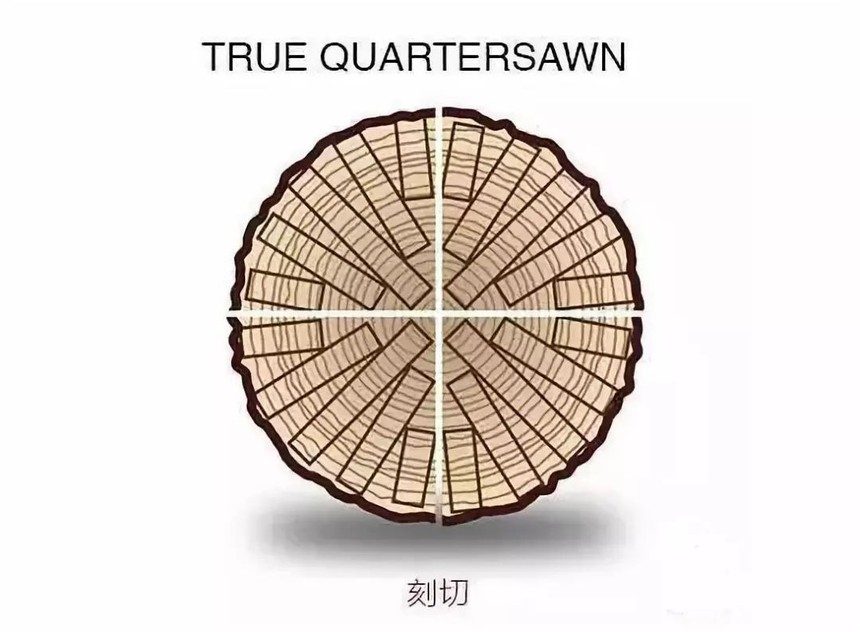

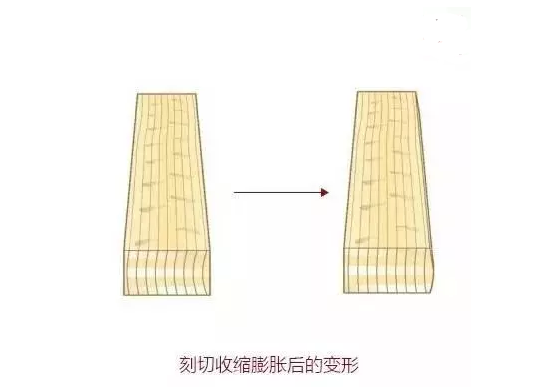

【Carved and cut】

The wood is cut into four equal parts, and then each part is cut and sawed. These wood boards close to the heartwood are called carved wood boards. The angle between the annual ring and the board surface is generally 60-90 degrees, and the resulting wood board has a smooth texture. Straight, often with a graceful tabby woodgrain.

advantage of engraving is that the stability is the strongest, the deformation is the smallest among the three cutting methods, and the disadvantage is the time-consuming consumables, which is the highest among the three cutting methods, so the price is also the highest.