The origin of the tenon and tenon joints began in the Hemudu period when the ancestors had the idea of detachment in order to build wooden houses. Therefore, the tenon-and-mortise structure originated earlier than Chinese characters. Thousands of patterns have been derived from tenon and tenon for thousands of years, but each has its own advantages and is suitable for different furniture. There are nearly one hundred basic shapes, and there are many derivatives.

Tenon processing

- The forming processing of the tenon and tenon grooves directly affects the processing quality of solid wood workpieces. During the processing, it is required to:

- Control the distance between the two tenons and the angle between the tenon cheek and the tenon shoulder;

- When tenoning at both ends, the same surface should be used as the reference;

- When placing components, there must be no debris between the planes.

Tenon and tenon and groove can be processed by sawing and milling, which are often done on the milling machine and tenon or tenon and groove machine; frame tenon and finger joint can generally be processed on a milling machine, and box tenon and dovetail tenon are processed on the tenoning machine.

The tenon processing in the milling machine is mainly based on the processing of the frame tenon, and the size calibration and truncating of the plate can also be processed by the circular saw.

The workpiece is successively milled by a circular saw blade tenon milling cutter head, an arc-shaped tenon shoulder is milled by an arc-shaped cutter head, and a longitudinal double tenon is cut by a disc milling cutter.

For the processing of right-angle tenon without longitudinal double tenon, it only needs to be processed by the first two stations.

Finish tenoning on tenoning machine Single-sided tenoning machine can process right angle tenon, right angle inclined shoulder tenon, and inclined tenon.

The double frame tenoning machine can process the tenon structure at both ends of the workpiece at the same time, and the dovetail tenoning machine is processed on the dovetail tenoning machine.

Tenon and mortise joint is the basic joint method of frame structure furniture. Parts joined in this way must have tenons, mortise, or grooves in the corresponding parts.

The traditional joint mainly adopts the form of right angle tenon and square tenon, dovetail tenon, and trapezoid tenon, etc. Modern furniture mainly adopts tenon joint forms such as long round tenon and long round tenon, round tenon and hole.

The matching accuracy of tenon and mortise has an important influence on the assembly quality of furniture, which is directly related to the convenience of assembly and the joint strength of the product. During the production process, the following points should be paid attention to:

- Strictly control the distance between the two tenon shoulders and the angle between the tenon cheek and the tenon shoulder, so as to adapt to the parts to be joined, so as to ensure the correct size and tight joint of the parts or products after joining;

- The machining accuracy of tenon and mortise is greatly affected by the state of the machine tool itself, the specification of the tool, and the adjustment accuracy. Therefore, when the machine is adjusted in production, trial production and trial assembly should generally be made first to ensure the matching accuracy;

- Whether the same datum plane is used for the precision cutting of the square material and the tenon opening will also affect the machining accuracy of the tenon and mortise. Therefore, the finishing of the wool material before tenon making must be standard, and the same positioning datum should be used as much as possible during tenon making;

- When making tenons, there should be no sawdust, shavings, and other debris on the worktable, and the processing should be stable to ensure the shape and position tolerance;

- The tenoning tool is kept sharp and dimensionally accurate to maintain the surface quality and dimensional accuracy of the tenon and mortise;

- The matching accuracy of tenon and mortise is affected by the temperature and humidity of the processing environment. It is necessary to prevent the assembly operation from being affected by poor matching caused by wood shrinkage and swelling.

Mortise processing

Matching with mortise, mortise also includes square mortise, oblong mortise, dovetail tenon, and round mortise, and the corresponding processing methods and equipment are also different.

Tongue and groove processing

In the production of solid wood furniture, the vertical and horizontal connections of square materials are often connected by tenons and rods, while the longitudinal connections are usually connected by tenon and grooves and tenon springs, and the horizontal connections along the width are often notch connections. In addition, there are some special grooves. (such as installing hinges or locks and other accessories), then we need to carry out tenon and groove processing.

Generally speaking, the tongue-and-groove fit along the fiber direction is commonly called a tongue-and-groove and a tongue-and-groove spring, the tongue-and-groove in the transverse fiber direction is commonly called a notch or a notch, and the partial non-penetrating notch is commonly called a notch, which is often collectively called a tongue-and-groove in actual production.

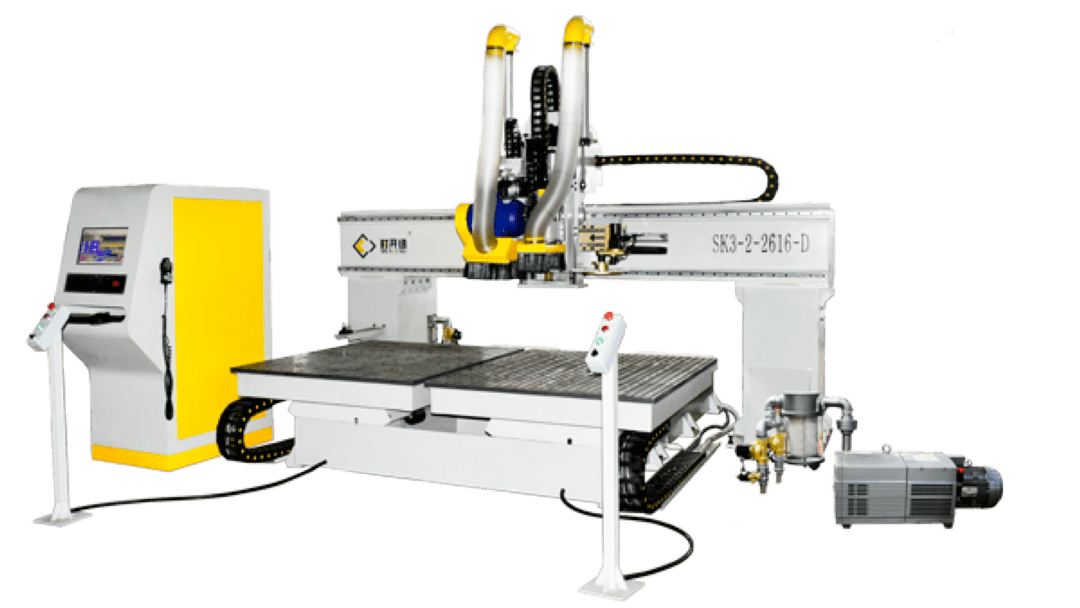

Shikainiu Mortise And Tenon-3Station adopt numerical control input and output, and a set of workpieces is positioned and processed at one time, ensuring high quality and high precision of the workpiece. It is suitable for machining workpieces of various shapes and specifications of tongue and groove (holes), especially for multi-mortise, small tongue and groove spacing, hole and groove combination, different length and depth of tongue, and groove of the same workpiece, and complex special-shaped workpiece processing. Advantage.

The tenon and tenon structure is an important genetic component of Chinese furniture. From ancient times to the present, the tenon and tenon production process has been continuously inherited and developed, and it is a beautiful treasure in Chinese craftsmanship and culture.