The batching process is the first step in the production and processing of solid wood furniture, the quality of batching process also directly affects the subsequent processing quality, production efficiency, and production cost.

As a natural growth material, wood has certain defects in the production of solid wood furniture, such as joints, scars, insect eyes, tree tumors, etc. If you want the furniture surface to be beautiful, you need to carry out batching procedures to optimize these woods before production and processing.

1. efficient batching process is a key step in furniture production

We often say that the ingredients are based on the comprehensive analysis of raw material size, defect and finished product size and grade requirements, and then make sawing plan for each piece of wood, apply the appropriate grade of wood to the appropriate position, and realize the maximum value of wood utilization.

To sum up, batching, as an important pre-processing section, needs to refer to the size, specification, and quality requirements of product parts, and then process them into woolens of various specifications and shapes. Its efficiency will directly affect product quality, material utilization rate, product cost, etc., is the key step of the entire furniture production

2. choose the quality of equipment is not only fast and high precision

Nowadays, with more and more automation equipment joining the ranks of furniture production, choosing quality preferred equipment can not only save materials but also ensure the efficiency of mechanical processing

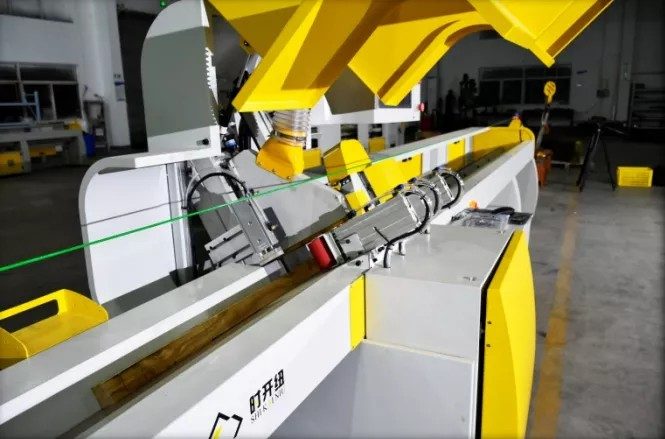

We learned that the latest preferred equipment of The time kaixin – selective truncation saw, whether from the product, design, material, or processing, can effectively for batch processing and material optimization, effectively bring good production benefits for the production enterprises.

SHIKAINIU Selected cutting saw SJ-260R

1. compared with the traditional batching process, the biggest difference is in its functional advantages

The traditional batching equipment relies on manual experience to judge the cutting position, while the optimized cutting scheme is optimized by comparing databases, and the output rate depends on its optimized program.

2. Reduce production process chain and improve production efficiency

Automatic selection can be made according to material defects to reduce manual selection time and improve processing efficiency.

3. Multiple installation methods to reduce the number of clamping

One placement, can complete the processing of multi-section materials, without waiting and program switching, convenient and fast processing

4. Reduce the occupied volume and reduce the production cost

Integrated different processing methods, increase a variety of processing functions, reduce the number of tooling, reduce the cost of equipment maintenance.

5. Smooth milling to ensure machining accuracy

The high-strength integrated fuselage not only effectively improves the accuracy of product processing but also meets the high precision requirements of different materials processing.

material samples

In addition, the selective truncation saw also has two major systems: multi-functional selective cutting system, automatic detection and feeding system, which can realize the selective preparation, suitable for the whole house customization, doors, and Windows enterprises, Chinese and new Chinese furniture enterprises.

Multi-functional combined cutting system

It can realize bending straightening, length optimization, value optimization, fixed cutting, supporting scanning code processing, tilting table, optimize the quality of fine cutting.

In addition, also has massive data storage, the system can also be set freely, easy to achieve to support scan code processing.

Automatic detection and feeding system

Automatic detection of material scarring and material length, automatic feeding according to the data, the maximum feeding speed up to 40m/min.

When the feeding system is backed up, the lines drawn on the material surface, as well as the length of the material, are scanned, and the computer is controlled to synchronize the data and optimize it.

a trick to win, select truncated saw ingredients in the production of significant effect

A selected truncation saw equipment with many advantages, can bring significant effects for enterprises, such as the reduction of the number of labor, production efficiency, processing range is wider, material cost reduction is no longer a fable, visible significant effects let more enterprises realize its strong advantages.