Five years ago, a company that could produce 100 sets of solid wood furniture of the same size a day was considered very powerful. But today, a company that can produce 100 sets of different sizes a day is amazing.

With more and more customization of whole wood, customized furniture with different styles and sizes is testing every furniture manufacturer, and fast delivery has become a bottleneck.

Therefore, it is imperative to create a fast road of informationization, so the solution based on “home intelligent manufacturing” came into being.

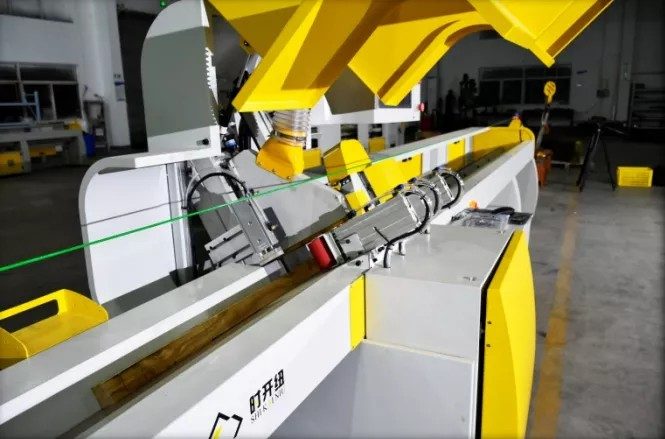

Through the development of intelligent manufacturing in recent years, intelligent furniture mortise and tenon processing equipment has created many “industry bests” such as automation, processing efficiency, and processing accuracy, and is an ideal choice for “mechanical substitution”.

ShikaiNiu CNC has been committed to promoting intelligent manufacturing in the home furnishing industry. Through in-depth cooperation with upstream and downstream design and production enterprises, we have achieved:

- Stand-alone production → online production

- Manual data input → scan code data transmission

- Manual statistical processing data → the system automatically captures production records

- Industrial control touch screen → in-depth customization of industrial control PC

- Modular system → module, CNC dual system, etc.

Compared with traditional machinery, what are the advantages of smart home manufacturing?

1. “Man-machine dialogue” is simple and convenient.

Modular programming, permanent use, can edit programs and upgrade machine functions through remote solutions such as the Internet.

2. High processing efficiency.

The complex and time-consuming process in traditional equipment processing is handed over to automatic mechanical processing, no need for cutting lines or molds, and the processing is completed in one clamping, which takes less time and truly achieves “mechanical substitution”.

3. High machining accuracy.

The size and tightness of the tenon and tenon hole can be achieved by changing the data modification, which can truly achieve “tight fit”, laying a solid foundation for the installation of the next process.

4. Higher safety performance and lower labor intensity for workers.

The machine tool is fully enclosed for processing. During the processing, the workers do not participate in the processing process. The workpiece can be completed only by loading and unloading the workpiece. Multiple processes are completed at one time. During the processing, work-related accidents are almost zero.

5. Adapt to various tenon processing.

Through program editing and selection, more than 60 kinds of tenon and tenon joints can be processed, covering almost all types of traditional tenon-and-mortise structures in classical mahogany furniture.

6. Environmental protection and energy saving.

The machine tool adopts central vacuuming, and the power of each tool axis is automatically switched during operation, and only one spindle motor works at a time.

Digital and intelligent technology can innovate and upgrade the industrial model. Based on digital technology, with the strong support of the Internet, Internet of Things, cloud computing, big data and other technologies, the industrial model of the manufacturing industry will undergo fundamental changes.

Therefore, no matter from which perspective, “Home Intelligent Manufacturing” is the core technology of the new round of industrial revolution.